Scenario

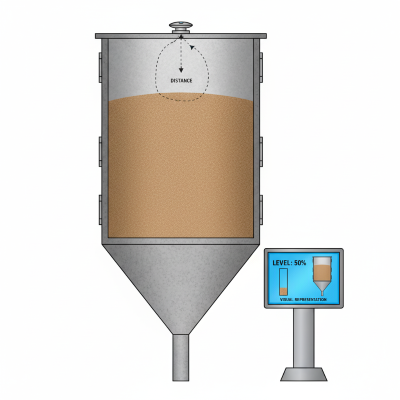

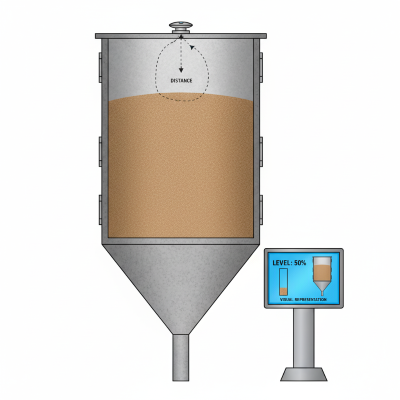

A brand new, cone-bottomed silo is installed and filled to capacity with a dry, granular product. The plant manager wants to monitor the volume of the product and has chosen to install a non-contact ultrasonic sensor at the very top. Before commissioning, the engineer is asked to write the code that will convert the measured distance to a percentage of total volume.

During the initial tests, with the silo at 100% and then 0% capacity, the sensor and code work perfectly. Later, with the silo half-full of product, the plant manager calls the engineer and says the level measurement is clearly wrong.

Why is the plant manager convinced the level is wrong, and what's the simple geometry oversight the engineer made in the initial calibration?

Answer and Explanation

The plant manager is convinced the reading is wrong because when the silo is half-full by volume, the level sensor will not show 50%. This is due to the shape of the silo. The conical bottom means that the first half of the volume fills the narrow, lower portion of the silo, while the second half of the volume fills the wider, cylindrical portion. The engineer's oversight was assuming a linear relationship between height and volume, which is only true for a perfect cylinder.

A more detailed breakdown of the geometry:

- The first 50% of the volume will occupy more than 50% of the overall height (because the cone is narrow at the bottom).

- The second 50% of the volume will occupy less than 50% of the overall height.

- The engineer calibrated the sensor for a perfect cylinder, but the cone bottom skews the relationship between height and volume.

- The solution requires a mathematical formula that takes the conical portion into account when converting the height measurement to a volume percentage.